![]() Home > Products >Home Appliance Mould

Home > Products >Home Appliance Mould

Fan blade mold belongs to the home application mould. According to the different product styles, the home application mould can be divided into traditional style and personalized style, such as plastic refrigerator part mold, PP cooler mold, air conditioner mold, etc.

Home Appliance Mould Overview

Fan Blade Mould

Taizhou Heya Plastic Mold Co., Ltd., as an emerging mould manufacturing company, has been absorbing the experience of its peers while integrating the company's own concepts to continuously improve the quality of Fan Blade Mould.

The company can customize Plastic Fan Blade Mold for customers according to customer requirements and supplemented by professional CAD/CAM/CAE design, CNC computer processing center, high-speed processing center, CNC lathe, EDM, wire cutting, milling machine and other high-precision processing equipment.

Informing your requirements of the product&mold and the detailed information of the matching injection molding machine will help us provide you with a quotation plan as soon as possible.

We look forward to reaching in-depth and long-term cooperation with you.

Product Name | Fan blade mould | ||||||||

Mold Shaping | China customized plastic injection mold | ||||||||

Mould Steel | S45C, P20H, 718H, 2738, S136,H13 etc. | ||||||||

Product Material | PP, PC, PS, PAG, POM, PE, PU, PVC, ABS, PMMA, etc | ||||||||

Mould Base | LKM, ISM, HASCO, DME | ||||||||

Cavity | Single/Multi-cavity as per customer needs | ||||||||

Mould life | 300,000 ~ one million shots | ||||||||

Runner type | Cold/Hot runner | ||||||||

Gate type | Pin -point gate, Submarine gate, side gate, etc | ||||||||

Delivery time | 30~60 days | ||||||||

Packaging | Standard Wooden Cases | ||||||||

Transportation | By sea or by air as clients requirements | ||||||||

Export Country | Worldwide | ||||||||

The main Mold Steel and Hardness for you reference: | |||||||||

Steel Grade | S50C | P20 | P20HH | 718H | 2738H | H13 | S136 | NAK80 | |

Hardness(HRC) | 17-22 | 27-30 | 33-37 | 33-38 | 36-40 | 45-52 | 48~52 | 34-40 | |

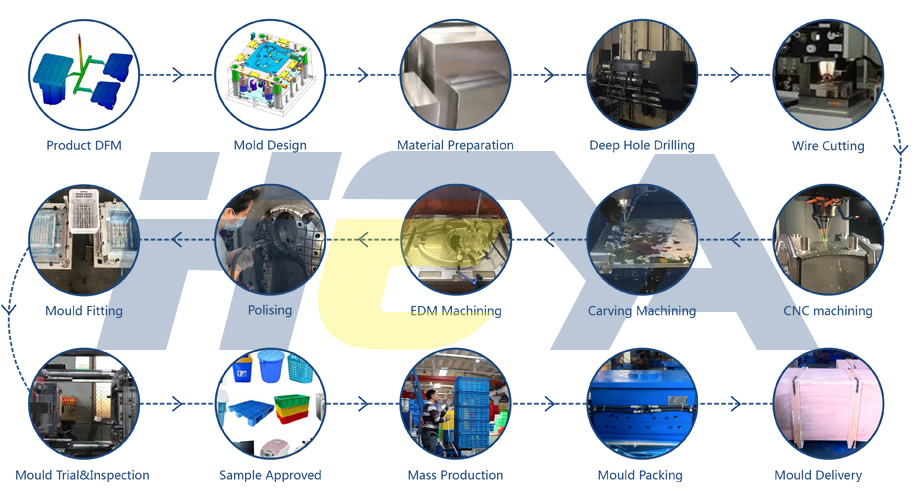

Basic Mould Processing

FAQ

Q:What's type of mould surface process do you use?

A:Heya Mold will customized it by your demand and mould specific, processing the mould surface like: Mirror polish; Texture; Chrome Plating treatment on the core and cavity; Nitride & vacuum heat treatment

Q: How to go to your factory?

A: You could come to Heya Mold factory by flight, train and bus.

There’s about 2 hours by flight from Guangzhou to Taizhou city; 3 hours by hight speed rail from Shanghai to Taizhou station;1 hour by train from Ningbo or Wenzhou to Taizhou station. 3 hour by bus or train from Yiwu to Taizhou station.

Q: How long is your mould delivery time?

A: It depend on the mould structure and size.

Generally it is 3~15 days for mould design, and 15~60days for mould production after Heya Mold received your deposit payment and mould design confirmation.

Why choose Us:

1. Adopt international advanced CAD/CAE/CAM software with an innovative and faster growing R&D team

2. From products design to mould delivery, supervised by one manager,

ensure no any problem.

3.Familiar with the structure of product and mold, suitable and stably structure of mold, which is easy to operate and maintain for clients.

4. Confidentiality,to comply with the basic business ethics and customer privacy

5. Assembly and packaging design, product CAN be used for terminal market sales

6. Efficient, treasure the time of customers and complete the excess of the work.

Fill in your phone and email information, will help us to get in touch with you in a timely manner,

as soon as possible to solve your problem

Add: No.17, Qingfeng Avenue, Huangyan District,

Taizhou City, Zhejiang Province, China.

Tel: +86-576-89161144

Fax: +86-576-89161144

Email: admin@heyamold.com