Heya Mould uses efficient and stable tools and software to design mould details for customers, including appearance, function and production efficiency.

Mold flow analysis includes: gate location, filling, temperature, pressure, volume shrinkage, weld line, air trap and deformation, etc.

Through mold flow analysis, it can assist runner design, shorten product development time and discover potential product problems in advance.

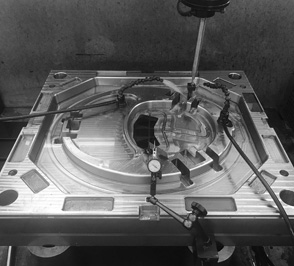

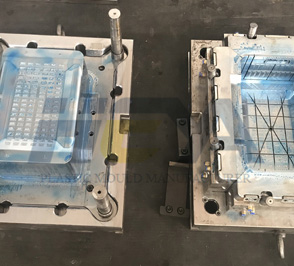

By simulating the opening and closing of the mold and the release of the product, the correctness of the mold structure is verified, and problems can be avoided in advance.

According to samples or client requests for product function and appearance, engineers will design the best mold solution through UG, CAD and other software.

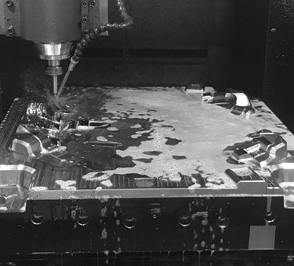

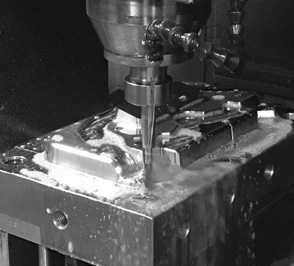

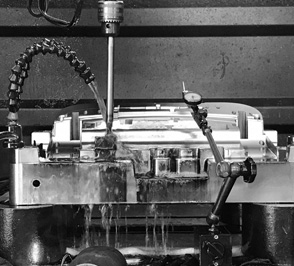

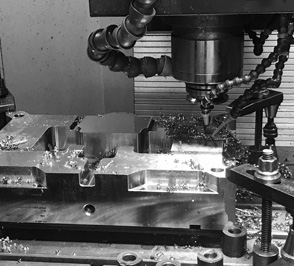

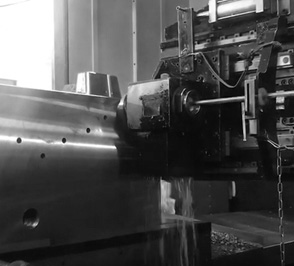

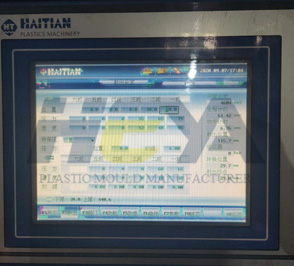

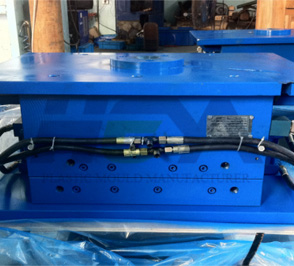

Heya Mold relies on the introduction of various advanced equipment , scientific processing technology and engineers with many years of experience to strengthen detail control and ensure the high precision, high quality and fast delivery of the mould.

Heya Mold provides customers with complete mold drawings and parts list before shipment, and saves complete mold operation and waterway test videos for customers within one year.

Add: No.17, Qingfeng Avenue, Huangyan District,

Taizhou City, Zhejiang Province, China.

Tel: +86-576-89161144

Fax: +86-576-89161144

Email: admin@heyamold.com